How much do you know about embossed aluminum coil sheet?

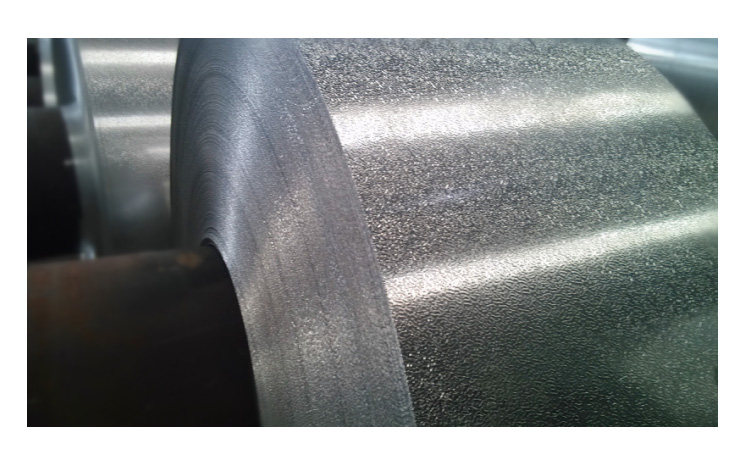

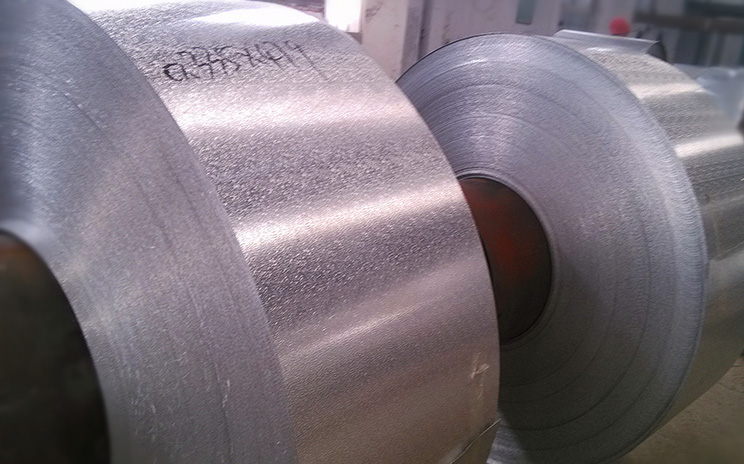

Embossed aluminum sheet can also be called aluminum embossed coil sheet: it is an aluminum product that forms various patterns on the surface after calendering on the basis of aluminum plate. It is widely used and is mainly used in packaging, construction, curtain wall, etc.

1. Aluminum alloy embossed aluminum coil: processed with 3003 as the main raw material. This aluminum plate is also called anti-rust aluminum plate. The strength is slightly higher than that of ordinary aluminum alloy pattern plate. Corrosion is not up to 5000 series of patterned sheets, so this product is used in rust prevention with less stringent requirements, such as truck models and cold storage.

2. Aluminum-magnesium alloy embossed aluminum coil: It is processed from 5000 series aluminum plate such as 5052 or 5083, which has good corrosion resistance, hardness and rust resistance. Usually used in special places, such as ships, cabin lights and humid environments, this kind of aluminum plate has high hardness and certain load-bearing capacity.

3. Ordinary aluminum alloy embossed aluminum coil: The aluminum alloy patterned sheet processed with 1060 aluminum plate as the base plate can adapt to the ordinary environment and has a low price. Usually cold storage decoration, the outer packaging uses this kind of patterned aluminum plate.

Features of Embossed Alumina Sheet: 1. Excellent fire and heat insulation performance: Embossed aluminum sheet will not melt after high temperature. When embossed aluminum sheet encounters fire or is exposed to high temperature, its excellent heat insulation function is only that its surface heats up rapidly. It quickly produces coke and has the effect of resisting flame extension and protecting the inner core from being burned. It has excellent fire resistance and thermal insulation properties.

2. Low cost: The density of the embossed aluminum sheet is low, so the quality of the embossed aluminum sheet under the same area is lighter, and the recycling value is high. At the same time, the service life of the embossed aluminum sheet is 3-5 times that of the iron plate. Users save a lot of labor and material costs.

3. Corrosion resistance: The embossed aluminum sheet has good corrosion resistance. Compared with the iron plate, the embossed aluminum sheet has a long service life. It is not easy to corrode and age in an outdoor environment, and the surface is beautiful. etc. embossed aluminum sheet is used as the anti-skid material.

4. The embossed aluminum sheet has a novel structure and good anti-skid effect, so the amount is large. The embossed aluminum sheet not only has a long service life but also can reduce the weight because the density of the embossed aluminum sheet is low.

5. Light weight and excellent durability. The mass per square meter is about 7kg and its tensile strength is 200Nmm2. The aluminum plate has a high elongation and a relative elongation higher than 10. It can withstand high bending without breaking and has good toughness.

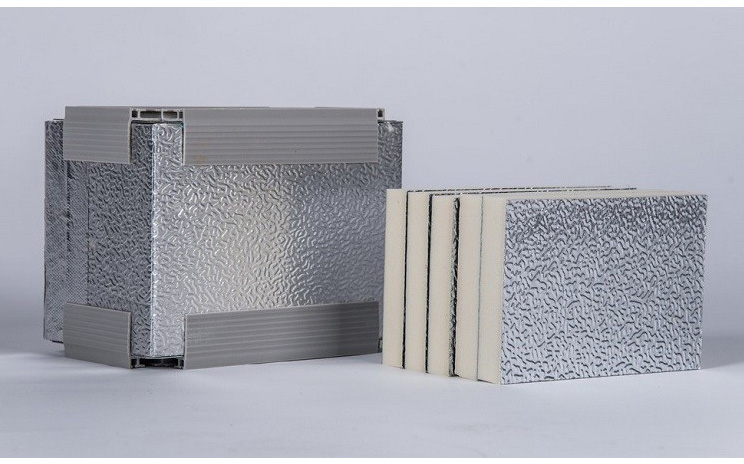

6. Strong decorativeness Different from the structure of other thermal insulation boards at home and abroad, the rigid polyurethane with low thermal conductivity and high thermal insulation performance is directly bonded to the back of the formed aluminum plate by infusion and foaming, and the decoration is strong.

7. The installation is quick and the process is reasonable. The embossed aluminum sheet is made on the factory assembly line and directly hangs on the building site.

The main application areas of embossed alumina board: architectural decoration (office buildings, hotels, high-speed railways, subways, airports, shopping plazas, stadiums, exhibition centers, villas, auto parts 4S stores, gas stations, bank buildings, bus stations, theaters, theme parks , ceiling), electrical appliances (refrigerators, air conditioners, washing machines, soymilk machines, audio, switch panels), electronic products (mobile phone shells, power banks), luggage, lighting, auto parts, gift boxes, etc.

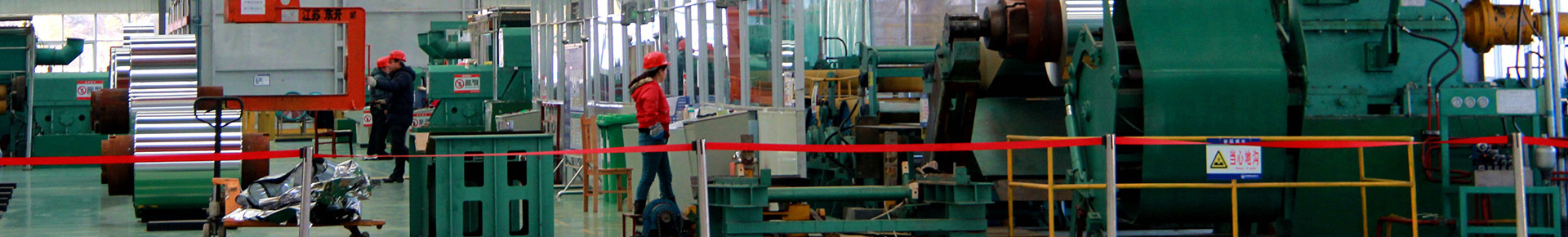

Henan SIGNI Aluminum has 16 years of experience in the custom production of embossed alumina sheets, and has more than 300 elite backbone teams with experience in R&D, design and production, which can fully cooperate with customers to solve the needs of product technology and quality characteristics; the company has introduced 65 units Intelligent precision CNC production equipment and 5 intelligent automatic coil production lines imported from Germany, support customized production, 24-hour evaluation feedback, 7-15 days fast production and shipment, guarantee customer delivery, welcome customers to come to consult and negotiate.

Hot Spot :

- Honeycomb Pattern Embossed Aluminum Sheet

- Anodized Aluminum Stucco Embossed Sheet for Refrige

- Automotive interior embossed aluminium sheet coil

- How much do you know about embossed aluminum coil s

- embossing aluminum metal panel

- 5052 O H32 embossing aluminum sheet

- 3005 H22 Orange peel embossing aluminum sheet

- Corrugated embossed aluminum sheet

- leather pattern embossed aluminum sheet

- Mirror polished cobblestone embossed aluminum sheet

- Water corrugated embossed aluminum coil

- Water corrugated embossed aluminum coil

- Embossed aluminum coil sheet introduce

- Embossed aluminum foil for phenolic composite board

- Gold silver anodized embossed aluminum electrical p

- Custom Embossed Aluminum Sheet for Home Appliance P

- 3003 embossed thermal insulation aluminum coil

- Textured aluminum coil sheet

- Flame Retardant Embossed Aluminum Foil

- 3003 H14 polysurlyn in embossed rolls

- Hemispherical embossed aluminum coil

- Embossed aluminum coil for interior decoration of c

- 1060 H24 embossed aluminium sheets

- Aluminium Pattern Sheet

- Embossed aluminum foil for composite duct

- 15 μm anodized surface aluminium stucco sheet

- 3D square embossing aluminium sheet

- embossed aluminum corrugated sheet

- 3105 3003-H24 Aluminum Stucco non directional

- lacquered aluminum stucco embossed foil for PIR ins

- Honeycomb pattern hexagon embossed aluminium sheet

- cylindrical concave-convex embossed aluminium sheet

- Woven pattern embossed aluminum sheet

- Hammer Pattern Embossed sheet for Lamps Reflectors

- Three-dimensional embossed aluminium sheets

- Perforated radiant barrier aluminium foil

- Hemisphere Embossing Aluminum heat shield

- Reinforced Scrim Embossed Aluminum Foil

- Hexagonal embossed aluminum foil

- Embossed coated aluminum coil sheet

- embossing aluminium sheet for 3D board core

- Polykraft Moisture Barrier (PKMB)clad stucco alumin

- 3004 -O embossed aluminium sheets for heat shield

- embossed aluminum wallpaper

- 5754 5052embossed aluminium coil sheet

- embossed aluminum coil for kitchen cabinets

- 0.09mm embossed aluminium coil

- 0.09mm embossed aluminium coil

- Custom embossed aluminum sheet coil

- Dot pattern embossed aluminum sheet for decoration

- laminate embossing aluminium foil for roof insulati

- pre cut embossed aluminium sheets

- emboss reflective metal sheet

- Embossed aluminum foil sheets for hairdressing

- Hemispherical embossed aluminum sheet 0.5mm

- Mirror pebble embossed aluminium sheet

- emboss painting aluminium sheet

- cosmetic stucco embossed aluminum sheet 12’’x48’

- Embossed aluminum sheet factory china

- Bean pattern mirror embossing aluminium sheet

- Diamond embossed aluminium sheet

- stucco aluminium roofing sheet

- metal mate stucco aluminium sheet

- stucco finish aluminium sheet

- Anodized embossed aluminium stucco sheet for fridge

- stucco aluminium duct cladding

- embossed metal sheets for heat insulation

- Spherical embossed aluminum sheet

- 0.4mm anodized stucco embossed aluminium sheet

- Orange peel embossed aluminum roll

- Anodized embossed aluminium sheet for Freezer liner

- A5052 temper O spherical embossed aluminum panel

- aluminium stucco cladding

- ASTM B 209 Alloy 5005 H-14 Aluminum Insulation Shee

- Insulated stucco panels

- embossed metal wall panels

- stucco embossed metal panel

- Embossed aluminium foil suppliers

- stucco embossed aluminum siding

- Stucco embossed metal panels

- embossed aluminium cladding sheet

- Laminated Aluminium Stucco sheet for insulation alu

- Diamond shaped aluminum coil sheet

- 1060 H18 Hammer-embossed mirror aluminium sheet

- BCO FOIL ALU/Scrim/PE

- Dot / Orange Peel/ Diamond/ Grid square embossed al

- Grid square pattern embossed aluminum coil sheet

- Grid square pattern embossed aluminum coil sheet

- Refrigerator anodized surface embossed aluminum coi

- Anodized dot embossed pattern aluminium coil

- Dot embossed aluminum sheet /coil

- Embossed aluminium sheet with PVDF coating

- Heat Shield Stucco Aluminium Sheet

- kraft paper embossed aluminum roll for pipe insulat

- Stucco embossed aluminum cladding for pipe insulati

- AA1100 Stucco textured sheet for evaporator

- stucco aluminium roofing foil sheet

- Antibacterial embossed coated aluminum foil

- Stucco Embossed Aluminum Sheets

- Stucco Embossed Aluminum Sheets for Sale

- Embossed aluminum sheet metal

- Stucco embossed aluminum coil

- stucco aluminium sheet

- Stucco embossed aluminum

- embossed aluminum sheet suppliers

- Aluminum stucco panels

- embossed aluminum sheet

- textured aluminum sheet

- 1100 1050 1060 Aluminum Coil Roll for Roofing

- Diamond embossed color coated aluminum coil sheet

- Color coated Embossed aluminum foil coil

- Embossed aluminum foil roll

- Round Square pattern Embossed aluminum sheet coil

- Embossed aluminum sheet coil manufacturer and suppl

- Blue anti-corrosion double-sided coated embossed al

- Square pattern embossed aluminum coil sheet

- Round point pattern embossed aluminum coil

- 3003 Kraft Paper Embossed Aluminum Coil

- Anodized embossed aluminium coil with protective fi

- Rhombic embossed aluminium sheet coil with color-co

- 1100 H18 orange peel embossed aluminium sheet whole

- 1050 O one layer embossed aluminium sheet for heat

- Polysurlyn moisture barrier stucco embossed aluminu

- Hammer embossed mirror aluminum sheet

- Anodized Embossed Aluminum Coil Manufacturer

- Hemisphere embossed aluminium sheet for heat shield

- Rhombic embossed aluminium sheet

- Orange peel embossing aluminium coil

- How much is stucco embossed aluminium roll with kra

- 1100 embossed aluminium sheet coil stock

- 8011 stucco embossed aluminium foil stock suppliers

- 3105 stucco embossed aluminium coil stock suppliers

- 1100 aluminum stucco embossed sheet stock suppliers

- 3003 aluminum stucco embossed coil stock suppliers

- Stucco embossed aluminum sheet suppliers for refrig

- Embossed aluminum roll coil for pipe insulation man

- Stucco Embossed Anodized Aluminium board for automo

- Stucco Embossed Kraft Paper Aluminum Roll China Sup

- Why use embossed aluminium sheet instead of flat al

- 3003 embossed aluminum coil and 5052 embossed alumi

- 1060 anodized Embossed Aluminum sheet Coil Manufact

- A1100,A3003 Stucco Embossed Aluminium Metal Sheet

- China embossed pre-paint aluminum sheet supply

- Embossing aluminium sheet

- Stucco embossed aluminum roll

- Anodized Aluminum Stucco Embossed Sheet Manufacture

- Aluminium stucco foil laminated kraft paper

- Why ventilation ducts need use 1050 stucco embossed

- Embossed aluminium sheet for heat shield

- 3003 H14 embossed insulation aluminum coil

- 3003 Stucco Embossedaluminum coil/ sheet for refrig

- What are the features of the stucco embossed alumin

- stucco embossed aluminium sheet suppliers

- Color coated embossed aluminum sheet production ste

- Oxidation embossed aluminum plate

- Coated embossed aluminum sheet

- 1100 1200 stucco embossed aluminum alloy plate

- Technical improvement of aluminium paper embossing

- Production method of embossed aluminium paper for c

- Production process of aluminium plate embossing

- Introduction of hemispherical embossed aluminium pl

- Introduction of aluminium roll embossing

- Why use the stucco embossed aluminum in the freezer

- Spherical stucco embossed aluminium

- Orange peel stucco embossed aluminum

- Advantages of stucco embossed aluminum evaporator

- Coated Stucco Embossed Aluminum Foil

- The sales of stucco embossed aluminum sheet in mark